在无损检测领域可以说,工业射线照相是最昂贵的方法之一。然而,在安全方面,由于有暴露于电离辐射的危险,它是独立的。由于环境危害,许多无损检测方法具有固有的安全风险,但射线照相是唯一具有高剂量辐射问题的主要方法。由于数字射线照相技术的引入,这些问题随着每一项创新而变得越来越小。

Modern equipment reduces the required overall radiation exposure to fractions of the original dose. This reduction in total dose allows the operation to take place in a much smaller square-footage than ever before, leaving more space for other trades to perform billable work. In fact, the right piece of equipment, though contracted at a higher hourly rate, could save a fabrication shop a considerable amount of money. Choosing the right modality could be the largest key to success.

数字成像选项的两大竞争者是计算机放射成像(CR)和数字探测器阵列(DDA)。每一种都有其自身的特点,使其在减少剂量方面有效,但每一种都有可能是关键的限制。CR手术可减少50%的辐射剂量,而DDA手术可减少75%以上的辐射剂量。

数字探测器阵列安全利弊

如果要检查的零件非常小或相对平坦,DDA可能是您问题的答案。然而,探测器阵列是刚性的,并且相对较厚,这使得在某些应用中很难使用。通过一些工程和修改,DDA面板可以安装在一个特定的位置,以便制造的零件通过“成像场”。该面板允许直接类型成像,不需要像CR或传统胶片那样的处理。

DDA面板还为射线照相装置提供了另一个奢侈品:目标墙。由于面板是刚性安装的,面板后面的地板或墙壁可以在一个专门的位置被重重地屏蔽。辐射源可以通过屏蔽聚焦,或者“准直”成一束大小合适的光束。这使被占领地区的辐射水平保持在较低水平,同时将高剂量的辐射对准未被占领地区。这也意味着屏蔽成本大大降低。而不是四个混凝土墙,一个暴露区域可以通过一个或两个。大多数采用这种安装方式的制造商还可以将曝光面积减少到胶片所需面积的四分之一。

然而,DDA确实需要一个安装和曝光计划来真正有效地减少时间。该装置可能需要定制,并由无损检测专业人员制定暴露计划。这些东西花费时间和金钱,但节省的钱可能是巨大的。一根长缝管,也就是一根长有焊缝的管子,在胶片上曝光可能需要一个小时,然后再加工半个小时。与DDA接触可能需要几分钟,无需二次处理。在这种情况下,总吞吐量可以缩短10倍。DDA有无数的自定义配置,因此它与许多制造零件相关。

Computed Radiography Safety

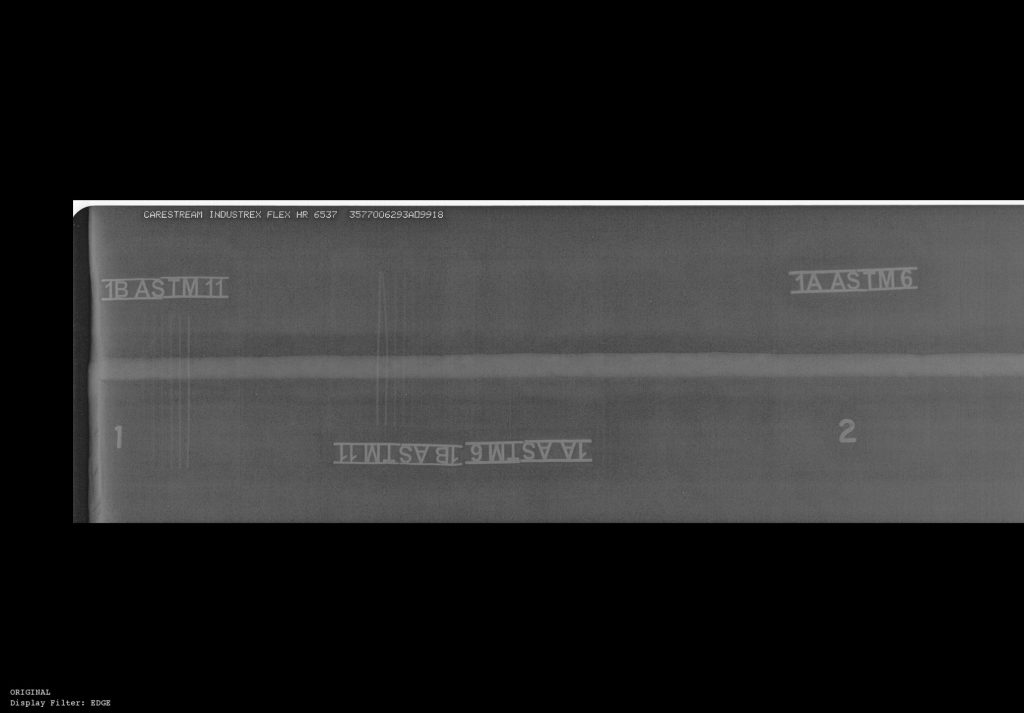

If your inspection subjects aren’t easily adaptable to DDA, computed radiography may be more appropriate. Some inspection subjects have complex configurations, making them complicated to handle. In the case of process or spool piping, configurations tend to be varied in diameter as well as length. Valves and other castings tend to have varying thicknesses along with a small bore. CR will excel in conforming to these parts. The reduction of the radiation dose is not as drastic as DDA, but a reduction of half is nothing to scoff at.

That same reduction could be made to the dimensions of the exposure area, allowing additional trades to work safely in the saved square footage. For construction sites, space is always at a premium. A smaller barricaded area means other workers won’t be shut down, making more productive hours throughout the site.

CR also has a portability comparable to that of film, so it can completely replace film operations with no real issues. For the time being, film is still the lower cost option. However, that will change in the future as film gets more expensive, harder to find, and less requested.

无化学工业射线照相术

CR和DDA共有的一点是无化学物质的过程。传统的暗室结构是围绕着在反应性化学品中处理银基薄膜。通常要注意确保化学品不会在现场丢失,然而,尽管发生泄漏的可能性很低,但绝不是零。一些放射技师没有遵循必要的步骤来防止泄漏,因此他们可能会留下泄漏供客户清理。

数字模式不需要化学物质来处理。如果需要二次处理,则通过应用能量传感器和传感器来实现。例如,CR需要二次处理来完成成像。这种处理是通过激光(刺激成像板)和传感器(称为PMT)实现的,而不是通过化学过程。DDA不需要二次处理,这会加快曝光速度,并使校正过程平稳快速。

This absence of chemicals makes for a cleaner environment, but also eliminates a maintenance step. Chemicals deplete over time which demands replacement. A portable darkroom must travel to an appropriate location for chemical dumping and a stationary unit would need to be changed on-site. This represents, roughly, 300-plus pounds of liquid chemicals requiring containment and secondary containment to avoid spillage. The cost of correct handling can be relatively high, but the incorrect handling may cost thousands in fines.

更安全、更经济的无损检测操作

选择CR或DDA而不是胶片有很多原因。减少对公众的辐射照射意味着,从长远来看,从事射线照相和非射线照相工作的人受到的辐射更少。射线照相操作的占地面积较小,使工人在较短距离内安全。无化学品处理也有助于任何场所的危险暴露。这些事情最终都会带来更安全、更具成本效益的运营。

Computed Radiography Webinar

Interested in learning more about the transition from traditional film to computed radiography? Click the link below to sign up for a webinar with the author, Wesley Soape.

Wesley Soape, ASNT NDT Level-III RT无损检测Technician, La Porte, Texas

P: 409.948.8494电子邮件:[电子邮件保护]